In the mining sector, efficiency is everything. Whether the operation involves large-scale gold extraction or small-scale industrial mineral production, how ores are crushed and ground determines everything that follows; product quality, recovery rates, energy use, and ultimately, profitability.

The mining process starts and ends with equipment. Poor choices at the crushing and grinding stages not only slow down production but also lead to avoidable losses and higher operational costs. From hard rock mining to industrial mineral processing, the demand for durable, precise, and energy-efficient machinery has never been greater.

Why Crushing and Grinding Are Foundational

Before any mineral can be processed or refined, it must be broken down. Crushing is typically the first step. It reduces large rocks or ore lumps into manageable sizes, which can then be subjected to more refined grinding processes.

This step is critical across sub-sectors:

- Metallic mining (e.g. gold, copper, iron)

- Non-metallic mining (e.g. limestone, barite, talc)

- Construction aggregates (e.g. granite, basalt, gravel)

- Industrial minerals (e.g. kaolin, bentonite, phosphates)

Each material responds differently to mechanical stress, and equipment must be chosen accordingly.

Jaw Crushers: The Frontline of Ore Reduction

One of the most widely used machines in primary crushing is the jaw crusher. It’s known for its simplicity, strength, and ability to handle a wide range of rock types and hardness levels. For miners and plant operators, jaw crushers offer:

- High throughput with minimal maintenance

- Efficient handling of tough materials like quartz and basalt

- Consistent size reduction essential for downstream processing

In many crushing circuits, jaw crushers set the pace for everything else. An effective crusher not only improves material flow but ensures that downstream grinders aren’t overloaded with uneven input.

To explore proven equipment options, Raymond Mills offers a range of high-performance jaw crushers designed for modern mining operations.

Fine Grinding: When Precision Becomes Profit

Once ore is crushed to manageable size, the grinding phase begins. This is where particle size is further reduced to liberate valuable minerals or achieve the fine powder specifications required for further beneficiation.

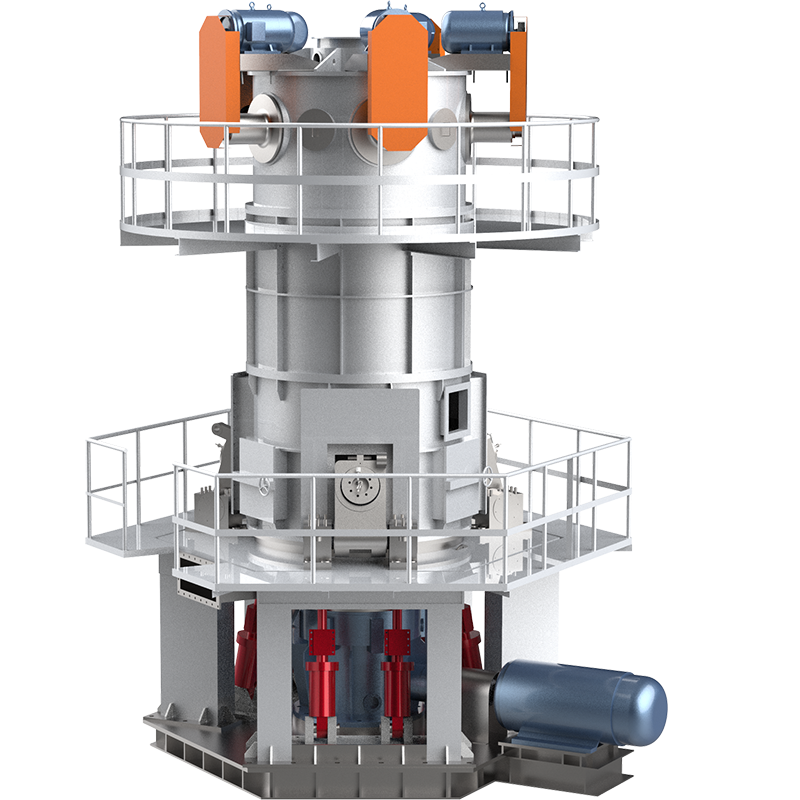

Traditional ball mills have long been the industry standard, but newer technologies now offer better results, particularly for ultra-fine applications. Among these, the superfine vertical roller mill stands out.

This type of mill delivers:

- Exceptionally fine and uniform particle sizes

- Lower energy consumption per ton of material

- Compact design ideal for space-constrained plants

- Reduced wear and tear over time

For mineral processors working with materials like calcite, dolomite, or heavy spar, a superfine vertical roller mill offers a practical way to improve yield and performance while reducing energy use.

Crushing and Grinding as Competitive Advantage

In the global mineral markets, selling unprocessed ore is no longer sustainable. Buyers demand uniformity, fineness, and consistency—whether the end use is in ceramics, metallurgy, or construction.

For this reason, mining companies across Africa, Asia, and Latin America are investing more in process optimization. That begins by upgrading their crushing and grinding lines. The right combination of primary crushers and precision grinders creates a stable, predictable output that supports every other stage of the production cycle.

Conclusion: Equip Right, Process Smarter

Across mining operations, whether in metallic ore extraction or industrial mineral processing, the efficiency of crushing and grinding systems directly influences output, cost, and long-term profitability. Getting the equipment right from the start is not just a technical choice, it’s a business decision.

For the initial reduction of raw ore, a dependable jaw crusher ensures stable, uniform feedstock that sets the foundation for downstream success. In the grinding stage, investing in advanced technology like a mill allows processors to achieve high-precision fineness with greater energy efficiency and reliability.

By aligning equipment choices with processing goals, mining enterprises can build more resilient, productive, and future-ready operations. Crushing and grinding may seem like routine steps, but when done right, they unlock the full value of the mineral resource.