Across industries like mining, construction, cement production, and metallurgy, the materials that often go unnoticed, lime and stone, form the backbone of entire supply chains. Whether it’s crushed stone used in concrete or calcium hydroxide in chemical treatment, these materials only become useful after proper processing.

As more countries in Africa and Asia prioritize industrial self-reliance and local beneficiation, investing in the right processing equipment becomes critical. This article explores two core systems powering lime and stone production today: stone crushers and lime production lines—both essential in turning raw materials into high-value industrial inputs.

The Role of Stone Crushing in Modern Industry

Stone crushing plays a foundational role in several industries, particularly construction, mining, and materials processing. In modern industrial setups, crushed stone is more than just a raw material, it’s a strategic input used to create everything from road bases and concrete aggregates to processed fillers in various industrial applications. The crushing process improves the material’s usability by reducing size, increasing uniformity, and enhancing handling efficiency. Efficient crushers enable producers to meet specific product size requirements and quality standards, which is vital for large-scale infrastructure projects and downstream mineral processing operations. As demand for high-performance construction materials continues to rise, reliable stone crushing systems remain critical to building and sustaining industrial capacity

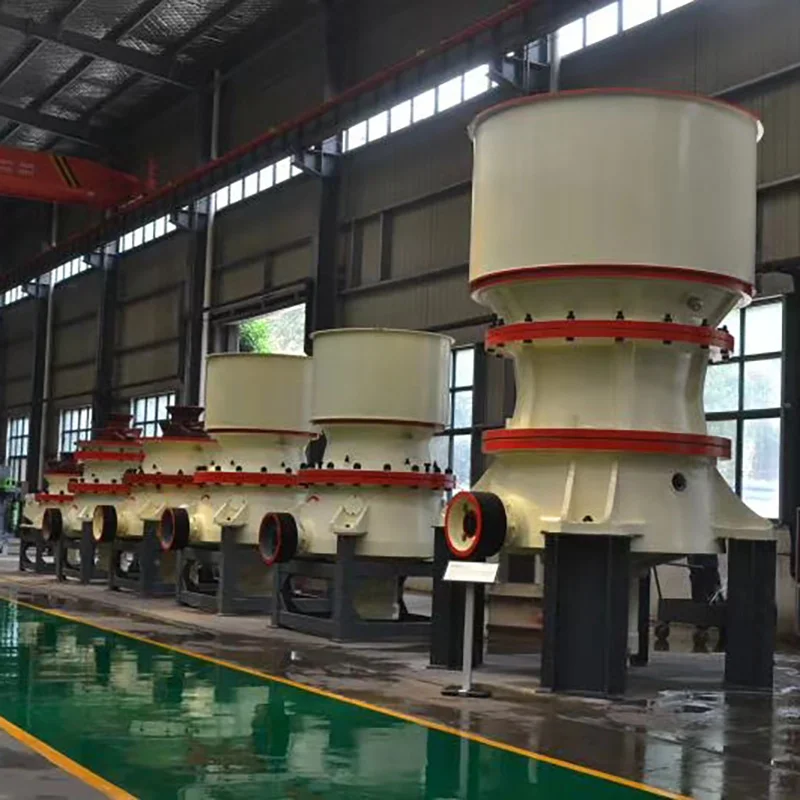

Among the many options available, the European Stone Hammer Crusher stands out for its versatility and performance in mid-hardness material applications.

Why the European Stone Hammer Crusher Works

The European Stone Hammer Crusher is built for industries that need reliability in primary and secondary crushing. It’s designed to handle materials such as limestone, granite, gypsum, and other aggregates. Here’s why it’s increasingly preferred:

- High crushing ratio: Efficiently reduces large rocks into uniform aggregates.

- Durable design: Built for long-term operation with minimal downtime.

- Adjustable output: Makes it suitable for multiple end-use requirements—concrete mix, road base, or fine powder preparation.

This type of crusher is particularly useful in stone-based industries that support construction, cement, and mineral beneficiation projects—especially where local quarries feed regional infrastructure growth.

Crushed Stone as an Economic Driver

Crushed stone is one of the most consumed construction materials globally. It’s a critical input for:

- Cement blending

- Concrete production

- Rail and road bed materials

- Industrial mineral processing (e.g. as feedstock for lime production)

For countries pushing industrial development, setting up efficient crushing systems using tools like the European hammer crusher helps ensure stable supply chains and lowers import dependence.

The Importance of Lime in Industrial Processes

Alongside stone, lime—in the form of calcium hydroxide—is another overlooked material that quietly powers major sectors. It’s used in:

- Flotation and pH control in mineral processing

- Water treatment and sanitation

- Flue gas desulfurization in power plants

- Soil stabilization in agriculture

- Chemical manufacturing

However, raw limestone must go through a chemical transformation to become usable lime. That’s where lime slaking systems and calcium hydroxide production lines are essential.

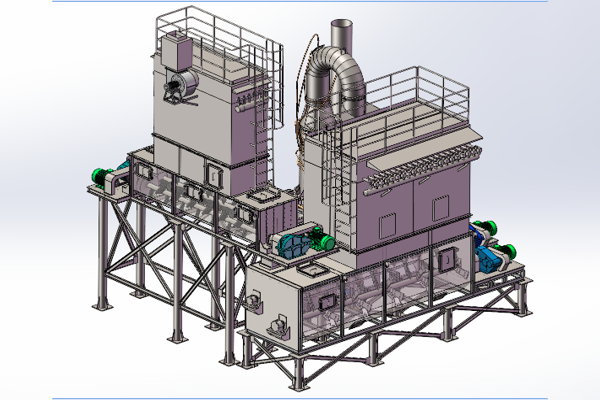

A Look into Calcium Hydroxide Production

A Calcium hydroxide production line is a complete system that transforms quicklime (CaO) into slaked lime (Ca(OH)₂) through controlled hydration.

Key benefits of a modern slaking system include:

- Consistent product quality: Ensures the calcium hydroxide meets industrial-grade specifications.

- Closed-loop operation: Reduces dust, improves safety, and minimizes material loss.

- Energy efficiency: Integrated systems that use less water and produce faster reactions.

These systems are crucial for processing plants that depend on reliable lime inputs—such as flotation plants in mining or municipal water treatment facilities.

Lime and Stone: Foundations of Local Processing

When paired, stone crushing and lime production provide a critical backbone for industries looking to localize inputs. For example:

- A mining operation might use crushed limestone for haul road construction and calcium hydroxide for ore flotation.

- A cement manufacturer can source its aggregate and lime from the same processing cluster.

- Governments focused on industrial value chains can stimulate job creation and domestic capacity by encouraging lime and stone production locally.

These aren’t just technical tools. They represent building blocks for economic development.

Conclusion: Equip Strategically, Scale Sustainably

In a global environment that increasingly favors localized, resilient supply chains, investing in essential equipment like stone crushers and lime production systems offers more than operational benefits—it’s a strategy for sustainable growth.

For processors working with limestone or aggregate materials, integrating tools such as the European Stone Hammer Crusher or a well-designed calcium hydroxide production line can transform raw potential into high-value output.

As more regions move from raw exports to refined, market-ready products, equipment like these become not only useful—but essential.